-

Automatic control

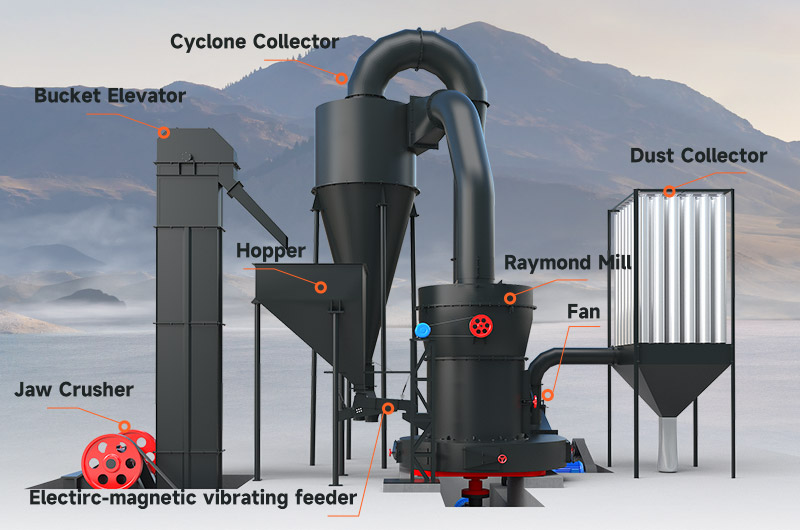

The electrical system adopts centralized control, the grinding workshop can be operated unmanned, and maintenance is simple and convenient.

-

High grinding efficiency

Fan and analyzer control fineness, eliminating screens and blockages, producing uniform powder (80–600 mesh) with over 99% passing rate.

-

Robust and Durable

With an integral gearbox, anti-vibration system, and parts like a grinding ring lasting 8,000 hours and a grinding roller up to 6,000 hours, this mill is designed to last over 30 years.

-

Environmental protection

The grinding process uses a closed-loop circulation system with negative pressure to minimize dust and noise. With a full-pulse dust collector, 99% of dust is removed.

-

Low energy consumption

Small footprint, high efficiency powder making, energy consumption is more than 60% lower than ball mill.