-

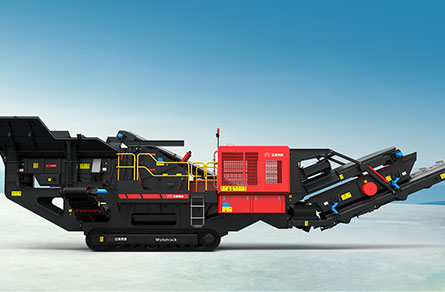

Using both oil and electricity.

The mobile stone crusher fuel consumption is low and can work efficiently.

-

Unit integration and flexible movement.

The mobile crusher eliminates the inconvenience caused by the site and complicated basic configuration. This reduces the cost of transportation.

-

Needn’t to lay foundation.

The performance of the crawler type mobile crusher is stable, after entering the site and work directly, which saves time and effort and, reduces the cost of investment.

-

Strong maneuverability.

The mobile crusher has a compact structure and small turning radius, so it is convenient for conversion, entering and exiting. Furthermore, it has low requirements for road transport loading conditions.

-

Energy saving and environmental protection.

The whole working process is sealed, producing less dust and noise, and equipped with professional dust removal and noise reduction equipment, which ensures environmental performance.